PRODUCT CATEGORY

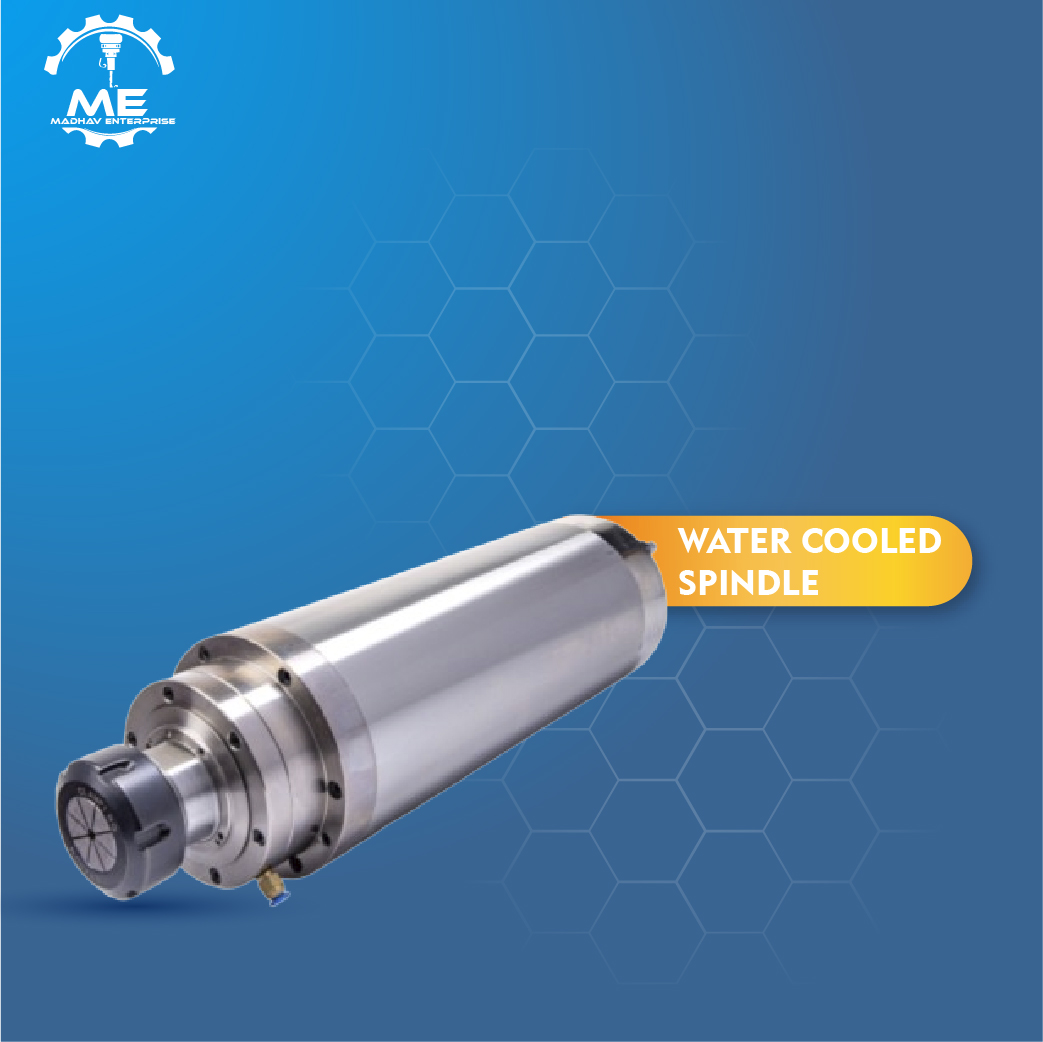

WATER COOLED SPINDLE

Description:

A water-cooled spindle is an integral component in CNC machining, designed to efficiently dissipate heat generated during high-speed operations like milling and engraving. Unlike air-cooled spindles, water-cooled variants employ a liquid coolant system, circulating water to absorb and transfer heat away from the spindle motor and cutting tool. Constructed from durable materials like aluminum or stainless steel, these spindles feature a compact design and integrated cooling channels. Water-cooled spindles offer superior heat dissipation, ensuring consistent performance and prolonging tool lifespan. They are ideal for demanding machining applications where precise temperature control and extended operation are essential.