PRODUCT CATEGORY

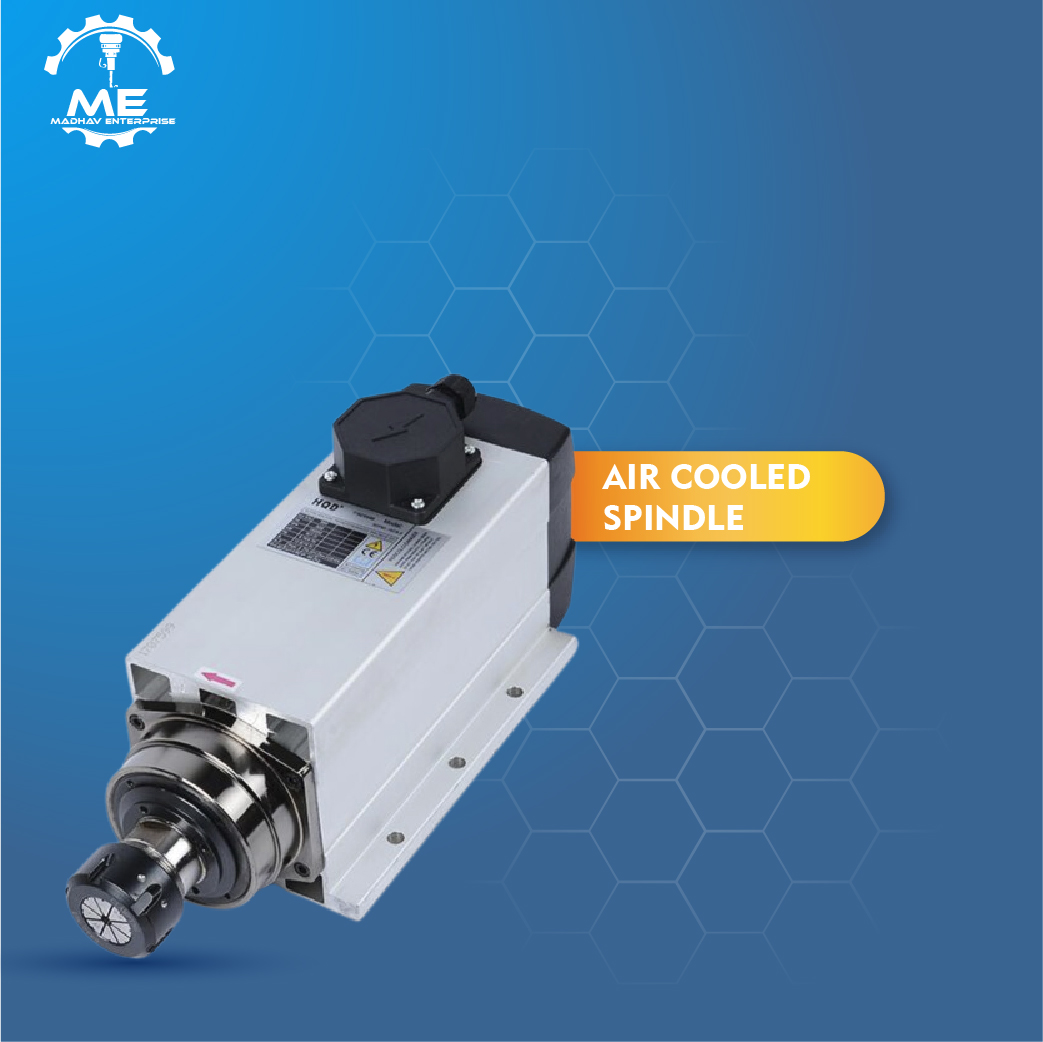

AIR COOLED SPINDLE

Description:

An air-cooled spindle is a crucial component in CNC (Computer Numerical Control) machining systems, utilized for high-speed material removal processes such as milling, cutting, and engraving. Unlike water-cooled spindles that rely on a liquid coolant system, air-cooled spindles dissipate heat generated during operation through airflow. Typically made from aluminum or steel, these spindles feature built-in fans or cooling fins to facilitate heat transfer and maintain optimal operating temperatures. Air-cooled spindles offer advantages such as simplicity, lower maintenance requirements, and suitability for smaller-scale CNC setups or environments where water cooling may not be feasible or practical. They are widely used in industries ranging from woodworking to metalworking for their reliability and efficiency.